Nominees for Packnorth Award 2025

At Empack 2025 on October 1 at 1:00 PM, the award ceremony will take place on the Empack stage.

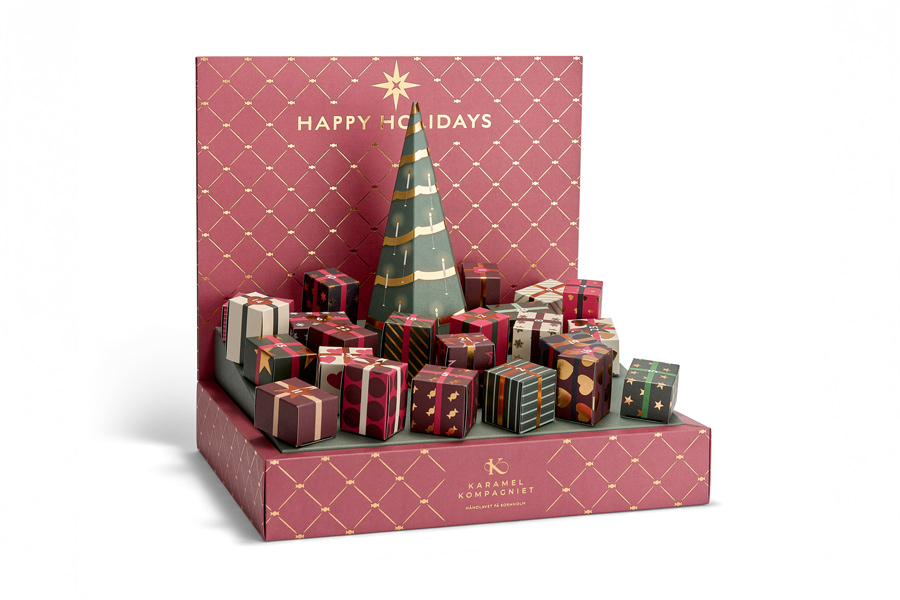

Category: Christmas calendars

Karamel Kompagniet – “Build-your-own” Christmas calendar 2025

The Danish company All Creative has produced this calendar for the Bornholm-based Karamel Kompagniet. It is described as an advent calendar that combines aesthetics, sustainability, and Scandinavian culture.

Inspired by the landscapes of Bornholm, the calendar is both a decorative part of Christmas celebrations and a practical storage for small gifts. It is delivered partially unassembled, creating a sense of togetherness and creativity when put together.

All materials are FSC-certified, and the calendar is designed to be reused year after year. To further promote sustainability, Karamel Kompagniet also offers a refill kit for use the following year.

Company: All Creative, Denmark

Lumene annual calendar 2024

Lumene’s advent calendar is unique and different every year. The contents also vary from year to year. Since the products don’t share a common shape, individual packaging is required for each item. This also limits the overall size of the packaging and optimizes the conversion process. All the small gift boxes are placed in the unglued top/bottom section.

The conceptual idea is to showcase Lumene’s origin: pure, natural ingredients from the clean, cold North. Visually, the Northern Lights and cold snow are highlighted in step 1. When you look deeper into this three-dimensional package, you’re actually digging into the snow in step 2: where plants and berries are revealed beneath the snow cover. Clever and minimal use of special effects supports the story—without compromising the sustainability of the concept. Step 3: is to “pick the berries” – open the box and receive the surprise.

Metsä Board uses Nordic fibers, holds PEFC certification, and prefers renewable energy in its production.

Company: Metsä Board, Finland

MR Cake Advent Calendar 2025

MR Cake’s advent calendar stands out by combining sustainable design, smart construction, and a unique consumer experience. The calendar consists of a lid-and-base package made from FSC-certified cardboard, with colorful printing that immediately conveys MR Cake’s well-known identity. Upon opening, the consumer is greeted by a three-dimensional city skyline in bold Christmas colors and gold foil, where each window appears as a small work of art. The individual windows have unique shapes—from trees and presents to characters—all numbered with gold foil for an exclusive look.

The construction is designed to be delivered flat, reducing both transport volume, costs, and climate impact. Once assembled, the calendar comes to life and becomes part of the Christmas decorations—a package that is as much an experience as it is a product.

Company: Avisera, Sweden

Category: Food packaging

Freeze-dried raspberries

The packaging is developed for restaurant and hotel kitchens where the pace is fast, the surfaces are exposed, and the demands for hygiene and reliability are high. It is based on collected, concrete feedback from professional chefs and head chefs about what doesn’t work with current solutions. More than 300 products have been developed, all sharing the same features. The solution is characterized by:

Quick identification and consistent design.

Clear brand concept: The name Ambrozia comes from Greek mythology, where ambrosia was the food of the gods.

Inspiration and knowledge on the label.

Moisture-resistant and easy to clean.

Level control at a glance.

Tightness and product protection.

Stackability.

Ergonomics adapted to large-scale kitchens.

Hygiene and glass-free safety.

Long shelf life after opening.

Company: Ambrozia AB, Sweden

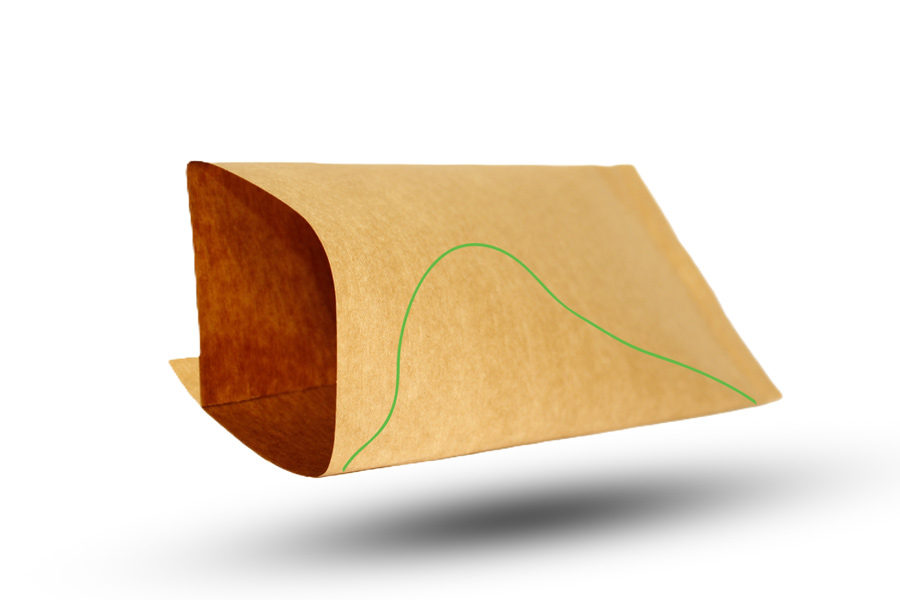

Paper wrapper for Panda chocolate bar

UPM Specialty Papers and Orkla Suomi have tested a new paper wrapper for Panda milk chocolate.

Orkla Suomi wanted to find a paper-based packaging solution that supports the goal of increasing the share of renewable packaging materials without compromising recyclability. During a six-month test period, the new wrappers replaced the traditionally used PP wrappers in stores across Finland. After the pilot phase in spring and summer 2025, the solution will be evaluated and a decision made on the next steps.

The new type of wrapper for Panda milk chocolate is based on UPM Asendo™ Pro 75 g/m² barrier paper, which has suitable grease barrier properties for Panda milk chocolate. A cold-seal lacquer, applied to the sealing surfaces, makes it possible to seal the paper-based packaging on Orkla Suomi’s existing flowpack machines, which are normally used for plastic packaging.

Traditionally, plastic or a paper-plastic laminate has been used in packaging to ensure durability, protect food, and prevent fat from penetrating the material. Thanks to the built-in barrier function of UPM Asendo Pro packaging paper, no additional plastic layer is required.

Company: UPM Speciality Paper/Orkla Suomi, Finland

Corrugated packaging for grocery deliveries

In collaboration with Nemlig.com, Denmark’s leading online grocery store, Smurfit Westrock has developed a corrugated box that complements the company’s existing delivery system and enables deliveries without the recipient needing to be at home.

Previously, Nemlig.com used rigid plastic crates with plastic bags inside, which required customers to be at home for delivery or to return the crates afterward—something that complicated both the customer experience and logistics.

The new paper-based box, which has been on the market for some time, was launched as an optional alternative and is designed to be fully recyclable while meeting Nemlig.com’s operational and automation requirements. The latest version, with new improvements, was introduced in the first quarter of 2025.

The corrugated box is designed to be stacked safely on top of both plastic crates and thermal boxes, supporting efficient loading and delivery. Reinforced corners ensure stable stacking even under pressure. A locking lid secures the box with a single hand movement—without the need for tape or extra materials—making it quick and intuitive to use.

The box is delivered flat and is automatically erected within Nemlig.com’s existing system, allowing it to integrate seamlessly into their logistics flow without disrupting current operations.

Company: Smurfit Westrock, Denmark

Category: Luxury packaging

Sjöman Partners Contract Box

Sjöman Partners’ contract box is a unique package that combines craftsmanship, quality, and brand identity at the highest level. The box consists of a rigid clamshell box, wrapped in dyed, uncoated paper with an embossed logo on the front, complemented by a custom-made metal sleeve specifically designed for the packaging.

The metal sleeve is embossed with Sjöman Partners’ emblem and logo, conveying a sense of weight, durability, and exclusivity—just as a real estate transaction should feel. A practical satin ribbon makes the box easy to open and adds a sophisticated detail to the user experience. Sjöman Partners’ packaging challenges tradition through material craftsmanship combined with modern design—showcasing innovation in premium packaging for the real estate sector.

Company: Avisera, Sweden

Diplomático Glass box

Diplomaticos’ premium packaging Glass Kit redefines exclusivity by combining innovation, craftsmanship, and sustainability.

The packaging consists of two rigid boxes, creating a seamless exterior without visible glue lines, perfectly angled 90-degree corners, and refined surfaces that enhance both the tactile feel and visual presence.

Designed with carefully selected sustainable materials, they unite structure, durability, and aesthetics. Every aspect—from material choices and finishing techniques to coordination with suppliers—has been managed to ensure flawless production and a sophisticated unboxing experience.

Glass Kit reflects the same uncompromising attention to detail and craftsmanship as the product it contains. This solution demonstrates how luxury packaging can merge function, aesthetics, and sustainability—strengthening brand perception and creating a memorable, elevated consumer experience.

Company: Motherland, Sweden

The Iconic Advent Calendar 2025

KICKS The Iconic Advent Calendar 2025 is not just an advent calendar—it is a packaging innovation that sets an entirely new standard in the category. With a unique construction of durable metal, wrapped in a graphic sleeve in a bold color combination, this is a calendar that truly stands out and captures attention.

What makes The Iconic exceptional are the carefully considered details. Behind the sleeve are four stackable metal boxes that open up to 24 individual compartments. Each compartment contains a reusable drawstring pouch in soft polyester, dyed in the same vibrant color as the sleeve, with matching grosgrain ribbon and small printed number tags. This creates a tactile and visual unity that enhances the user experience.

To give the calendar a personal and creative twist, it also includes a decorative sticker sheet that allows consumers to design and adorn their own boxes. Each calendar thus becomes unique and customized—an interactive detail that makes the experience even more memorable.

Through the choice of premium materials and a construction built to last, The Iconic transforms from a classic single-use package into a product with long-lasting value. The boxes can be reused for storing makeup, accessories, or on a desk—a calendar that lives on long after Christmas is over.

Company: Avisera, Sweden

Category: Circular/sustainable packaging

Muoto Twin Uncoated Fibre -series

Muoto Twin Uncoated Fibre products are untreated, smooth, molded fiber items made from renewable wood fiber sourced from Nordic forests. The products are plastic-free and manufactured without added PFAS, yet remain water- and grease-resistant for use in food service and take-away. Thanks to new technology, internal barrier properties and a multilayer structure are achieved, enabling lightweight design, strength, and stability—all key quality attributes. The products are recyclable, biodegradable, and approved for food contact. Our supply chain is fully transparent and traceable.

Muoto Twin products have a distinctive design that can be scaled to different shapes and sizes. The current product portfolio includes formats such as plates, bowls, and clamshell packaging.

The new manufacturing method is highly resource-efficient, modular, and fully automated. Production can be integrated into a bioproduct mill, and Muoto Twin products require no additional processing later in the supply chain. They can be used by industry, food service, and households alike.

Company: Metsä Spring, Finland

Re-Zip

The interest in reusable packaging is growing rapidly. Together with Rajapack, major e-commerce players, and logistics partners, RE-ZIP’s packaging has shown promising results in Southern Europe.

Here’s how it works:

As easy to use as a regular cardboard box, but it can be returned, cleaned, and reused multiple times.

It meets European standards and reduces CO₂ emissions by up to 80 percent after five uses.

Returns are free and simple for the customer, thanks to the printed QR code. The customer can easily fold the box, scan it, and return it via designated collection points.

Rajapack receives the returned packaging, performs a quality check via the app to ensure it can be reused, and prepares it for the next delivery cycle.

Company: Rajapack, Sweden

No-Tape Transport Box

ChatGPT sade:

This retail and transport box for Orkla’s “New Energy” bars combines two key features in one design: a self-locking bottom and a lid that requires no tape. The result is a box that is quick to assemble, easy to handle (improving ergonomics during packing), and completely free from additional sealing materials.

The tape-free design speeds up and simplifies packing, reduces material usage, and makes recycling easier for both logistics and retail staff. The construction holds securely during transport and opens neatly at the point of sale, making it ideal for shelf-ready presentations.

By completely removing tape from the process, the box reduces complexity, waste, and the risk of contamination in the recycling stream—clear proof of how small changes in structural packaging can deliver measurable improvements in efficiency and recyclability. A timely improvement in line with upcoming packaging regulations.

Company: Smurfit Westrock, Sweden

Category: Take-away packaging

Muoto Twin Uncoated Fibre -series

Muoto Twin Uncoated Fibre products are untreated, smooth, molded fiber items made from renewable wood fiber sourced from Nordic forests. The products are plastic-free and manufactured without added PFAS, yet remain water- and grease-resistant for use in food service and take-away. Thanks to new technology, internal barrier properties and a multilayer structure are achieved, enabling lightweight design, strength, and stability—all key quality attributes. The products are recyclable, biodegradable, and approved for food contact. Our supply chain is fully transparent and traceable.

Muoto Twin products have a distinctive design that can be scaled to different shapes and sizes. The current product portfolio includes formats such as plates, bowls, and clamshell packaging.

The new manufacturing method is highly resource-efficient, modular, and fully automated. Production can be integrated into a bioproduct mill, and Muoto Twin products require no additional processing later in the supply chain. They can be used by industry, food service, and households alike.

Company: Metsä Spring, Finland

Beverage packaging 9-pack

The “Brewery Box” from T-Emballage is a completely new type of packaging solution specifically developed to optimize farm sales of beverages. In spring 2025, Swedish breweries were granted the opportunity to sell directly from their premises, which created new packaging needs—namely, the ability to sell beverages packaged for the customer in sets of nine bottles. The standardized packaging solutions previously available on the market were usually designed for six to eight bottles or cans.

The unique aspect of this solution is that despite the challenge of creating a 9-pack, the packaging has been constructed from a single sheet. It is designed with nine compartments and an integrated insert that provides stability and protection, while also highlighting the product and the customer’s brand through three windows on each long side. The design meets the requirements of the new legislation, meaning it allows sales of up to three liters per customer—an important step for beverage producers wishing to sell directly to consumers.

The solution can be varied and adapted for different types of bottles and cans in the 33 cl format.

The packaging is not just protection for the contents—it is part of the experience, a way to communicate craftsmanship, quality, and identity directly to the customer.

Company: T-Emballage, Sweden

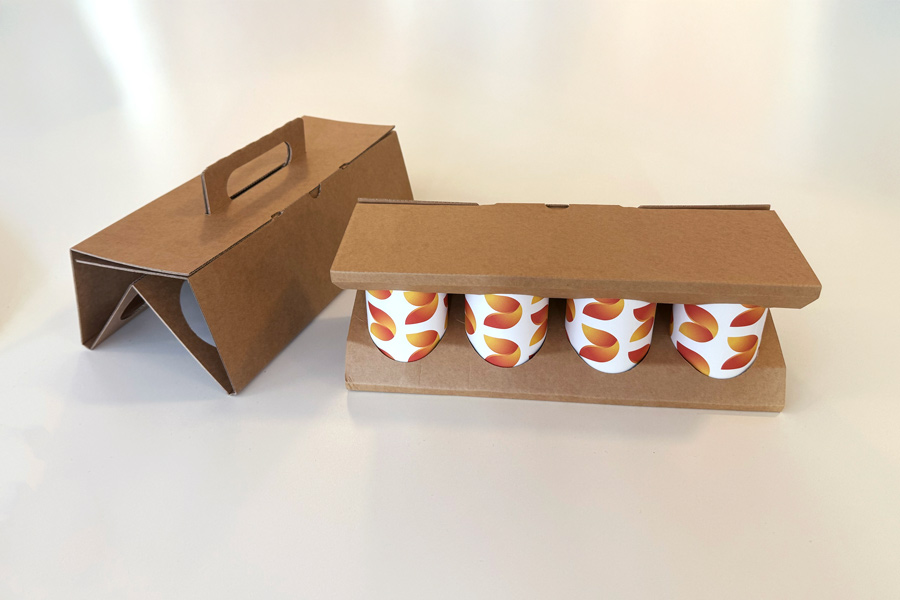

Stadium Meal Carrier

The Stadium Meal Carrier is an innovative, user-focused packaging solution designed for football fans and stadium visitors, developed by Smurfit Westrock, Denmark.

Created for Odense Boldklub’s football stadium, this carrier solves the challenge of transporting multiple drinks, meals, and snacks from the concession stand to the seat.

Traditionally, fans have struggled to balance food and drinks, often leading to spills or multiple trips back and forth. This solution securely holds two drinks, two meal trays (stadium plates with sausage and bread), and two bags of candy or snacks in a lower compartment beneath the trays.

The ergonomic design allows it to be carried with one hand, improving the fan experience and reducing accidents. The product is delivered flat with a conical shape and is quickly assembled without tools, making it easy for staff to pre-assemble and stack them efficiently.

Made from corrugated board, it is both sturdy, lightweight, and 100 percent recyclable. The carrier requires minimal additional material while significantly improving convenience and guest satisfaction. Printing options also make it possible to feature stadium branding and sponsors.

Company: Smurfit Westrock, Denmark

Viking Tray

In autumn 2025, the fast-food chain Sibylla will launch a campaign burger called the Viking Burger. The meal includes fries and a drink, and to enhance the Viking atmosphere of the dining experience, the fries will be served in a specially designed tray shaped like a Viking ship.

The overall impression and sense of a well-thought-out concept are important in encouraging guests to choose campaign products like the Viking Burger. The devil is in the details, and the tray adds that little extra while remaining functional. The campaign will be marketed with a Viking-themed commercial. The packaging board CrownBoard Prestige is used, giving the tray an elegant touch, which is also important for the overall concept.

The tray is easy for staff to assemble (with a crash-lock bottom) and just as easy for the guest to fold up after eating. It consists of a single piece of die-cut paperboard. Because it folds easily, more trays can be recycled in the same container over time. But in the best-case scenario, Sibylla believes younger guests will happily take the ship home as a trophy—making its lifespan even more significant.

Company: Nordic Fast Food AB, Sweden

Category: Industrial packaging

Tray with lid for automated flow

Wellplast has developed an innovative tray designed for automated processes in medical technology—where function, hygiene, and sustainability work together in a circular packaging system.

The tray consists of two parts: a lid and a base with openable flaps. The construction enables stackability and efficient handling in automated flows. The openable side allows robots to open and empty the tray without manual handling—streamlining processes to such a degree that one customer chose to adapt their machinery to this packaging.

The material meets strict cleanliness requirements for medical technology applications and food, without releasing dust or fibers. It works as a carrier in ETO, autoclave, and radiation sterilization, and withstands humid environments, making it suitable also for chilled and frozen products. The ability to package directly in clean zones eliminates the need for repacking, washing, or disinfecting items such as return crates.

Made from 100 percent polypropylene, the tray is fully recyclable in existing systems without requiring disassembly. It meets EU requirements for reusability, material recycling, and easy sorting. Its high strength and chemical resistance make the material ideal for medical technology applications.

The tray is lightweight yet durable, reducing material usage, simplifying handling, and minimizing environmental impact during transport. It can be used as either single-use or reusable packaging—contributing to resource efficiency without compromising function. Delivered flat, it reduces volume, shipping costs, and emissions—an important aspect of sustainable logistics solutions.

Company: Wellplast, Sweden

Solid board produce box with integrated corner support

Smurfit Westrock Lagamill has developed a solid board transport box for fruit and vegetables that eliminates the need for separate plastic corner reinforcements without compromising stacking strength.

The design reuses board material that was previously discarded during die-cutting to reinforce the corners, creating a strong, load-bearing structure without extra components.

This single-material solution reduces the number of parts, simplifies production, and streamlines recycling, while also supporting efficient logistics through intelligent structural design. The solution was launched in early 2025.

85% of the packaging consists of recycled material.

Company: Smurfit Westrock, Sweden

Powertools – Machine box and insert

The Finnish company Orapac was commissioned by its customer Mirka to further develop the packaging solution for their five sanding machines in the power tools segment.

The challenge was to create a unified packaging design with a specially adapted insert that fits all models—something the previous solution did not allow. The existing packaging was time-consuming to pack and posed workplace risks, such as cuts and strain injuries.

The new construction is designed to be ergonomic, easy to pack, visually appealing, and user-friendly for the end customer. At the same time, it contributes to cost savings through smart material choices and more efficient logistics.

Orapac replaced a complex insert made of C-flute with a simpler E-flute construction, reducing material usage without compromising functionality. In addition, the outer box is now printed with offset instead of flexo printing, eliminating the need for expensive printing plates and providing greater flexibility for design changes.

Company: Orapac Oy, Finland

Category: e-commerce packaging

Cardboard divider

Rajapack’s self-adhesive divider is designed to effectively secure products during transport by keeping them in place and absorbing shocks and vibrations. Perfect for e-commerce and logistics sectors, it offers a simple and reliable solution for protecting small to medium-sized items.

Place the product in the box and attach the divider where needed to hold it securely. Then press lightly on the divider to ensure it sticks firmly.

Examples of use in shipments include packaging of small electronic devices, protecting cosmetic products, securing items such as jewelry and watches, as well as fixing irregularly shaped objects for e-commerce shipments, such as glass jars, candles, and more.

Company: Rajapack, Sweden

Cut it EVO footprint reduction

Proteinbolaget, active in health foods and fitness products, is an e-commerce company that faced a major challenge. The number of orders was steadily increasing, and their packing process was in urgent need of automation. Manual packing was highly labor-intensive.

They also had eight different box sizes for their various orders. This meant keeping a large stock of both boxes and filler material.

With the help of Ranpak and e-motions, and using Cut’it! EVO packaging technology combined with volume analysis, they managed to reduce the eight box sizes down to just one. The box is cut to exactly match the height of the contents, down to 55 mm. The volume of packaging material, filler material, and boxes in storage was reduced dramatically, while at the same time more orders could be packed with fewer staff.

Company: Ranpak, Sweden

Mobile phone box made of paper

An innovative and protective box for mobile phones where the product is held securely in place with the help of a paper insert. Its construction protects against shocks and vibrations during transport.

Ready to use straight away—place the phone inside and fold the box. It seals with a self-adhesive strip and opens with a zip/tear strip.

Suitable for tech companies, the second-hand market, and more.

Company: Rajapack, Sweden

Category: Beverage packaging

Beverage packaging 9-pack

The “Brewery Box” from T-Emballage is a completely new type of packaging solution specifically developed to optimize farm sales of beverages. In spring 2025, Swedish breweries were granted the opportunity to sell directly from their premises, which created new packaging needs—namely, the ability to sell beverages packaged for the customer in sets of nine bottles. The standardized packaging solutions previously available on the market were usually designed for six to eight bottles or cans.

The unique aspect of this solution is that despite the challenge of creating a 9-pack, the packaging has been constructed from a single sheet. It is designed with nine compartments and an integrated insert that provides stability and protection, while also highlighting the product and the customer’s brand through three windows on each long side. The design meets the requirements of the new legislation, meaning it allows sales of up to three liters per customer—an important step for beverage producers wishing to sell directly to consumers.

The solution can be varied and adapted for different types of bottles and cans in the 33 cl format.

The packaging is not just protection for the contents—it is part of the experience, a way to communicate craftsmanship, quality, and identity directly to the customer.

Company: T-Emballage, Sweden

Can carrier for farm sales

DS Smith has developed a packaging range for farm sales to meet market needs following the new farm sales legislation that came into effect this past summer.

In collaboration with first-year packaging design students from Brobygrafiska, they created a smart package that works both as a display and is ready to be carried home!

Thanks to its design, the cans are highlighted on the shelf, and the built-in handle makes it easy to carry after purchase.

The packaging is delivered flat and is easy to fold and fill with products.

The concept is also adaptable for different numbers of cans, various design solutions, and custom printing.

Company: DS Smith, Sweden

Diplomático Discovery Box

The Diplomático Discovery Box is a newly developed tasting package that replaces a previous solution used in other countries. It was redesigned with vertical placement of the sample tubes, allowing the box to also function as a stable tasting stand and display. It was created for Diplomatico/Just Drinks’ virtual tastings. The shape and finish enhance the premium feel and strengthen the brand experience.

The packaging offers several advantages, such as:

2-in-1 transport packaging + ready-made tasting stand/display.

Reusable: can be used for multiple tastings, extending its lifespan.

Improved usability: vertical layout provides quick overview and easy handling during tasting/streaming.

Premium execution: material and finishing choices that elevate exclusivity and presentation.

Company: Motherland, Sweden

Category: Biomaterial-based packaging

Woodmer Seal

Woodmer Seal is a new fiber-based heat-seal coating for packaging. Developed from renewable wood biomass, it offers a greener alternative to traditional plastic coatings, such as polyethylene, with up to 90 percent lower emissions. It is not only environmentally friendly—it is also performance-driven, ensuring strong, reliable heat seals for e-commerce, industrial, and agricultural packaging with barrier properties against grease and water vapor.

This new material is built on innovation inspired by nature’s own technology—biomimetics—the same principles used in the structural design of plants. Ecohelix technology is an efficient way to utilize an underused side stream from pulp production. The technology is the first of its kind and unlocks access to a previously hard-to-exploit resource: the lignin/hemicellulose side stream. The core technology uses membrane filtration and enzymatic treatment to create a new polymer with adjustable and controllable properties.

The secret lies in creating a copolymer with high molecular weight, high charge density, broad pH range, and amphiphilic properties.

These qualities provide film-forming, adhesive, and thermoplastic properties, making it a highly functional polymer for a wide range of packaging solutions.

The material enables nearly 100 percent fiber-based monomaterial packaging, which significantly improves recyclability.

Applications include flexible packaging for non-food items, e-commerce, personal care and cosmetics, as well as industrial and agricultural packaging.

Company: Ecohelix, Sweden

Muoto Twin Uncoated Fibre -series

Muoto Twin Uncoated Fibre products are untreated, smooth, molded fiber items made from renewable wood fiber sourced from Nordic forests. The products are plastic-free and manufactured without added PFAS, yet remain water- and grease-resistant for use in food service and take-away. Thanks to new technology, internal barrier properties and a multilayer structure are achieved, enabling lightweight design, strength, and stability—all key quality attributes. The products are recyclable, biodegradable, and approved for food contact. Our supply chain is fully transparent and traceable.

Muoto Twin products have a distinctive design that can be scaled to different shapes and sizes. The current product portfolio includes formats such as plates, bowls, and clamshell packaging.

The new manufacturing method is highly resource-efficient, modular, and fully automated. Production can be integrated into a bioproduct mill, and Muoto Twin products require no additional processing later in the supply chain. They can be used by industry, food service, and households alike.

Company: Metsä Spring, Finland

Prepac ReUse

Prepac ReUse is a circular and reusable tray, manufactured in Sweden. Fifteen percent of the material is bio-based.

The design makes it easy either to eat directly from it or to remove all the food effortlessly.

The tray is extremely durable and scratch-resistant and can be sealed at least 400 times. It is stackable and easy to separate from the stack.

The material can be recycled and reused to make new trays at least 10 times.

Food can be packed in a modified atmosphere with vacuum and gas to extend shelf life.

After use, it can be sent back to Solserv, which ensures it is recycled and used in new trays. Customers receive a 20 percent discount when purchasing new trays.

The packaging was fully launched in 2025, but had already been tested for some time with strong interest from municipalities and hospitals as well as the private sector, companies, and others.

Company: Solserv, Sweden

Category: Student

Origami Lightbulb Packaging

Students Beata Tapola Jakobsson and Sofie Josefsson from Haganässkolan in Älmhult have redesigned the typical light bulb packaging so that it can be reused by the consumer to create a lampshade.

In this way, 80 percent of the packaging material is repurposed into a DIY project that encourages consumers to be creative with the material instead of just throwing it away. Beata and Sofie believe this will create positive associations with reuse and inspire more creativity among consumers when it comes to upcycling materials and objects. The hope is that the packaging will also encourage consumers to make more conscious decisions regarding the environment and their own impact.

The construction is also designed to work without glue or any additional materials—both for closing during packing and for reshaping into a lampshade.

The packaging comes in two sizes: one for a single light bulb and one for both a bulb and a cord/pendant—a complete kit.

The prototypes are made of Invercoat carton. Since 80 percent of the packaging is repurposed into a lampshade, only a small portion ends up in the recycling bin. However, the carton is fully recyclable and reusable.

Beata Tapola Jakobsson and Sofie Josefsson, Haganässkolan, Älmhult

Reusable Christmas calendar

Susanne Hollstedt from Nackademin in Stockholm has designed this reusable advent calendar. With its 24 decorative boxes, it can be filled with anything from candy and small toys to beauty products—or why not a little piece of jewelry for each day? The contents are chosen by the user, making the calendar as personal as it is atmospheric.

Instead of traditional prints, the design features elegant cut-outs and carefully selected color combinations. This version comes in white, gold, silver, and classic red—but the calendar can easily be adapted to other color schemes to suit different styles and homes.

The round shape makes the calendar a beautiful interior detail in itself. At its center is a space where you can place a string of lights, creating a warm, soft glow that spreads Christmas spirit and brightens the winter darkness.

This prototype has not yet been made from recycled material, but the ambition is to use recycled carton in larger-scale production. Naturally, the carton is FSC-certified, ensuring it comes from responsibly managed forests—a conscious choice for a more sustainable future.

Susanne Hollstedt, Nackademin